Maintenance, while one of the most important parts of any business, has been slow to evolve. For most companies, work orders are handled the same way they were fifty years ago.

75% of companies still use paper, spreadsheets, or nothing at all to manage maintenance tasks and work orders. In a digital business landscape, this can create a bottleneck that leads to unhappy customers and costly production downtime.

With the right software solutions, you can optimize your work order process and remove obstacles to essential maintenance which could be keeping your business from working optimally.

What Is a Work Order?

A work order is a task order sent by a customer or organization, usually for a service technician.

A work order must be reviewed and accepted by the provider for a customer to receive an ETA and cost or time estimate.

Many industries use work orders to manage maintenance and repairs. A work order is often the result of a routine inspection where the inspector finds issues.

The work order pad of the past

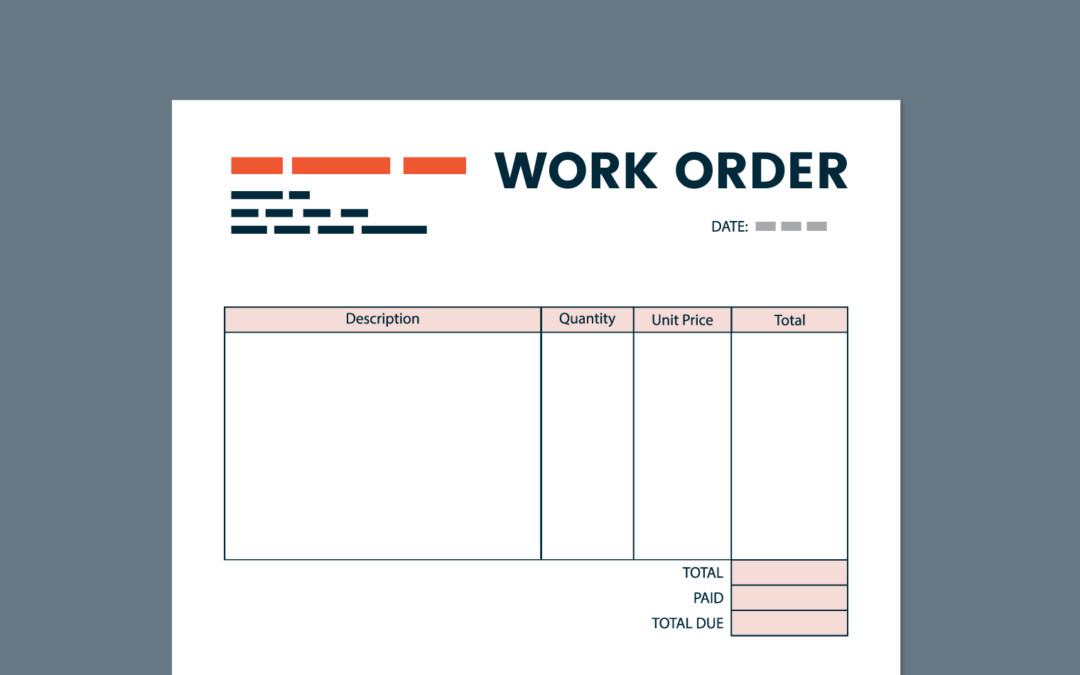

Before the digital revolution, many companies handled their work orders using a snap-off (tearable) work order pad.

Something like this:

The inspector or maintenance worker would bring a pad like this one to inspections and write a work request on-site. Managers would get a copy for bookkeeping purposes.

But those days are over.

Work order management software: the modern solution

Instead of a physical pad, modern companies use work order management software to handle their maintenance workflows.

With it, your business can share private request forms with external clients or internal workers as well as easily create new work orders digitally.

You can then handle the work order online and keep track of all projects in a single dashboard, making it easy to follow up on any project.

Who Uses Work Orders?

Work orders are used across a lot of industries in which ongoing maintenance or small jobs are a part of the client relationship.

Field service companies

Field service companies use work orders to efficiently stay in control across a wide variety of maintenance tasks that need to be done for their clients.

Facility management companies

Facility management companies use work orders to track expenses related to maintaining client buildings.

Technicians

Technicians, like electricians and field engineers, use work orders to track expenses and working hours for specific projects.

Manufacturers

Manufacturing companies mainly use work orders for internal service requests and to track the status of repairs and expenses.

Managed computer services

Managed computer services companies use work orders to track client issues and downtime as well as managing their computer techs and expenses.

General contractors

General contractors can use work orders to handle the expenses and workflow for every part of a building project.

Within a company, the work orders may come externally from clients or internally from technicians during an inspection.

For example, a customer of a building management company might use a work order for maintenance requests for a broken sink or AC.

In manufacturing, a plant manager might find a faulty robot arm and send in a work order to ensure the plant keeps running smoothly.

Final Thoughts

For a small business with only a few customers, filing and managing work orders might not be your biggest problem to solve.

But once you hit a certain scale, any field service company is going to struggle.

Maximizing the number of work orders your existing team can handle will help you maintain healthy profit margins, keep customers happy, and drive more revenue.

This article originally appeared on optimoroute.com.